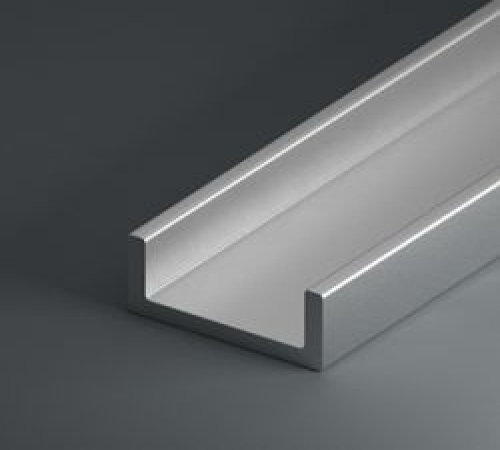

Aluminum Channel

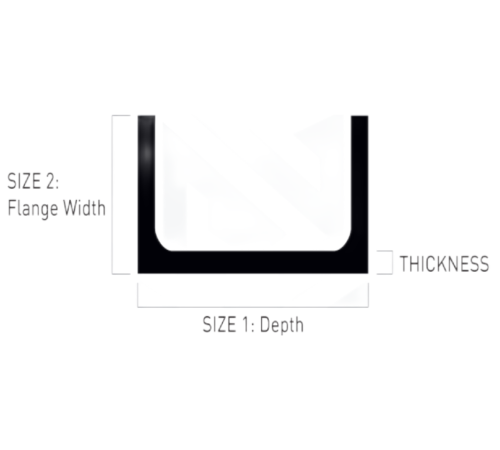

Aluminum channels are a special type of aluminum extrusion used for a variety of structural applications. The primary characteristics of a common aluminum channel include two flanges protruding from one side of a web that often resemble the letter C in cross-section.

Aluminium Grade: 6Series

Depth: 6.8-602mm(or customized according to the drawing)

Flange Width: 2.7-257mm(or customized according to the drawing)

Thickness: 1-12mm(or customized according to the drawing)

Length: Customized according to the drawing

Temper: O, H116, H112, H14, H22, H24, H32, H111, H16, H36, F,etc.

Certificate: ISO9001, CNAS, OHSAS

Packing: blank waterproof paper, kraft, wooden case or pallet (fumigation report for the wooden packing material)

Features: very good elongation, anti-corrosion performance

Overview of Aluminum Channel

Aluminum channels are a special type of aluminum extrusion used for a variety of structural applications. The primary characteristics of a common aluminum channel include two flanges protruding from one side of a web that often resemble the letter C in cross-section.

Features of Aluminum Channel

An aluminum channel is a structurally sound metal component that is made by the extrusion process to produce shapes, forms, and designs for a wide variety of applications. The major benefit of aluminum channels is their weight, which is one third the weight of steel without sacrificing durability and reliability.

Applications of Aluminum Channel

Aluminum U & J channels both offer a large range of applications across many industries. The most common uses for these types of channels include framing, tracks, slides, protective edges, railings, rails, rims, and decoration, to name just a few.

Manufacturer of Aluminum Channel

Staral Alloy is a professional aluminum supplier, providing users with different types of aluminum products. The price of aluminium is not only low, but also has high corrosion resistance. We strictly control the production process of each product to ensure high quality.

Chemical Composition of 6Series Aluminum Alloy Channel

Component Elements Properties | Metric | English | Comments |

Aluminum, Al | 91.7 - 99.6 % | 91.7 - 99.6 % | Average value: 97.0 % Grade Count:185 |

Bismuth, Bi | 0.15 - 1.5 % | 0.15 - 1.5 % | Average value: 0.616 % Grade Count:25 |

Boron, B | 0.0030 - 0.060 % | 0.0030 - 0.060 % | Average value: 0.0543 % Grade Count:10 |

Chromium, Cr | 0.030 - 0.40 % | 0.030 - 0.40 % | Average value: 0.150 % Grade Count:159 |

Copper, Cu | 0.010 - 1.2 % | 0.010 - 1.2 % | Average value: 0.326 % Grade Count:185 |

Cr + Mn | 0.12 - 0.50 % | 0.12 - 0.50 % | Average value: 0.323 % Grade Count:3 |

Iron, Fe | 0.040 - 1.0 % | 0.040 - 1.0 % | Average value: 0.467 % Grade Count:184 |

Lead, Pb | 0.0030 - 2.0 % | 0.0030 - 2.0 % | Average value: 0.318 % Grade Count:19 |

Magnesium, Mg | 0.20 - 3.0 % | 0.20 - 3.0 % | Average value: 0.833 % Grade Count:185 |

Manganese, Mn | 0.020 - 1.4 % | 0.020 - 1.4 % | Average value: 0.274 % Grade Count:172 |

Nickel, Ni | 0.050 - 0.20 % | 0.050 - 0.20 % | Average value: 0.100 % Grade Count:3 |

Oxygen, O | 0.050 - 0.50 % | 0.050 - 0.50 % | Average value: 0.275 % Grade Count:9 |

Silicon, Si | 0.20 - 1.8 % | 0.20 - 1.8 % | Average value: 0.725 % Grade Count:181 |

Strontium, Sr | 0.050 % | 0.050 % | Average value: 0.0500 % Grade Count:8 |

Tin, Sn | 0.050 - 2.0 % | 0.050 - 2.0 % | Average value: 0.850 % Grade Count:19 |

Titanium, Ti | 0.010 - 0.25 % | 0.010 - 0.25 % | Average value: 0.131 % Grade Count:148 |

Vanadium, V | 0.050 - 0.30 % | 0.050 - 0.30 % | Average value: 0.148 % Grade Count:16 |

Zinc, Zn | 0.030 - 2.4 % | 0.030 - 2.4 % | Average value: 0.216 % Grade Count:177 |

Zirconium, Zr | 0.050 - 0.20 % | 0.050 - 0.20 % | Average value: 0.109 % Grade Count:7 |

Zr+Ti | 0.15 - 0.20 % | 0.15 - 0.20 % |

Mechanical properties of 6Series Aluminum Alloy Channel

Mechanical Properties | Metric | English | Comments |

Hardness, Brinell | 25 - 130 | 25 - 130 | Average value: 88.3 Grade Count:71 |

Hardness, Knoop | 73 - 163 | 73 - 163 | Average value: 121 Grade Count:47 |

Hardness, Rockwell A | 35.5 - 49.5 | 35.5 - 49.5 | Average value: 43.0 Grade Count:33 |

Hardness, Rockwell B | 49 - 88 | 49 - 88 | Average value: 67.6 Grade Count:39 |

Hardness, Vickers | 35 - 149 | 35 - 149 | Average value: 106 Grade Count:49 |

Tensile Strength, Ultimate | 89.6 - 565 MPa | 13000 - 81900 psi | Average value: 333 MPa Grade Count:97 |

Tensile Strength, Yield | 40.0 - 517 MPa | 5800 - 75000 psi | Average value: 282 MPa Grade Count:97 |

Elongation at Break | 1.0 - 35 % | 1.0 - 35 % | Average value: 11.0 % Grade Count:93 |

Modulus of Elasticity | 67.0 - 140 GPa | 9720 - 20300 ksi | Average value: 84.1 GPa Grade Count:77 |

Compressive Yield Strength | 365 - 490 MPa | 52900 - 71100 psi | Average value: 423 MPa Grade Count:3 |

Compressive Modulus | 96.0 - 121 GPa | 13900 - 17500 ksi | Average value: 107 GPa Grade Count:3 |

Ultimate Bearing Strength | 228 - 1080 MPa | 33100 - 157000 psi | Average value: 830 MPa Grade Count:6 |

Bearing Yield Strength | 103 - 1100 MPa | 14900 - 160000 psi | Average value: 749 MPa Grade Count:6 |

Poissons Ratio | 0.296 - 0.33 | 0.296 - 0.33 | Average value: 0.327 Grade Count:54 |

Fatigue Strength | 55.0 - 517 MPa | 7980 - 75000 psi | Average value: 170 MPa Grade Count:32 |

Machinability | 30 - 90 % | 30 - 90 % | Average value: 64.6 % Grade Count:26 |

Shear Modulus | 25.8 - 53.8 GPa | 3740 - 7800 ksi | Average value: 28.1 GPa Grade Count:53 |

Shear Strength |

Send an Inquiry

Your email address will not published. Required fieled are marked.