What is Aluminum Alloy Forges?

Aluminum or aluminum alloy forged articles are called aluminum forgings.

Features of Aluminum Forges

1. Low density

2. The surface is smooth and clean, with good surface treatment performance, beautiful and durable.

3. High specific strength, high specific rigidity, high specific elastic modulus, and high fatigue strength. It is applicable to key stressed parts with high lightweight requirements, and its comprehensive performance is far superior to other materials.

4. The internal structure is fine, uniform and free of defects, and its reliability is much higher than that of aluminum alloy castings and die castings, and also higher than that of other metal castings.

5. The aluminum alloy has good plasticity and can be processed into high-precision forgings with complex shapes. The machining allowance of parts is small, which is only about 20% of the aluminum alloy round bar plate.

6. Aluminum alloy forgings have good corrosion resistance, thermal conductivity and non-magnetic properties, which are incomparable to steel forgings.

Applications of Aluminum Forges

1. Aluminum profiles are used in automatic assembly lines and material transfer equipment manufacturers. Industrial aluminum profiles can be customized to support automatic assembly lines, such as conveyor line support, stacker and shuttle rail, etc.

2. Aluminum profiles are used in production equipment workbench of electronic industry. The workbenches and operation consoles in the electronic industry are all assembled from aluminum profiles and aluminum alloy plates or other materials.

3. Aluminum profiles are used in automatic production lines of packaging industry. The automatic production line in the packaging industry is generally a belt conveyor line workbench customized by aluminum profiles, which is transported while packaging.

4. Aluminum profiles are used in the worktable of industrial detection system. The workbenches of the industrial detection system are the operation workbenches and detection workbenches. These workbenches are made of aluminum alloy profiles, which are not only anti-corrosion but also very easy to clean.

5. Aluminum profiles shall be used for assembly of parts in automobile industry. The parts assembly industry needs not only workbenches but also industrial fences and aluminum profiles for mold opening. Many auto parts are also customized from aluminum profiles.

6. Aluminum profiles are used in chemical, pharmaceutical, medical and food industries. The application of aluminum profiles in the chemical, pharmaceutical, medical and food industry is reflected in the application of workbenches and dust-free purification workshops. The performance of aluminum alloy with high anti-corrosion hardness and high cleanliness meets the needs of this industry.

How to customize aluminum forges?

1. Design product samples: we can send our own needs or sample drawings to the aluminum processing plant. The processing plant will make a quotation according to the sample drawings and section size. The quotation is generally divided into mold opening fees and material fees. If deep processing is required, there will also be processing fees. If you feel that the quotation is within your acceptable range, you can open the mold.

2. Trial mold: the processing manufacturer will process a sample according to the drawing. After the mold is opened, we'd better check whether the quality, size, thickness, etc. of the trial mold sample meet our needs, and how the sample meets our requirements. We will place an order for mass production.

3. Batch production requires advance deposit: before batch production, a certain amount of deposit needs to be paid to the processing plant. If the aluminum products produced do not need to be further processed, the aluminum products can be packaged and shipped. After arrival, the balance can be paid off.

4. Deep processing: if the produced aluminum materials need to be deep processed, first determine the deep processing drawings, and then batch deep processing of aluminum profiles can be carried out after the drawings are determined, such as drilling, cutting, tapping, etc.

The above is the process of customizing industrial aluminum profiles. If you need to customize die opening aluminum profiles, you can contact customer service!

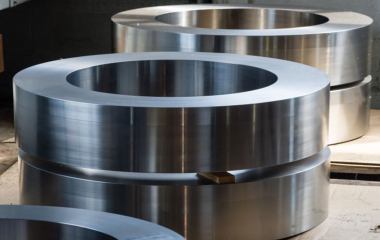

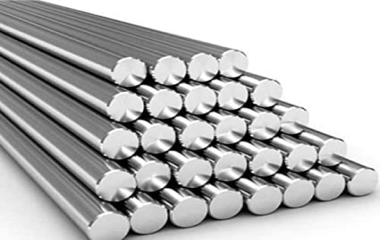

Available Size for Aluminium forges

The company mainly produces super thick aluminum plates; High precision aluminum alloy cold drawn tube/bar; Aluminum forgings; Large diameter thin (thick) wall pipe, profiled pipe, waveguide pipe, reducer pipe, gradual change pipe, tapered pipe, water drop shaped pipe, etc., the maximum outer diameter is 560mm, the minimum wall thickness is 0.5mm, the maximum length is 12m, and the accuracy tolerance is ± 0.03m; It can also provide a variety of large section aluminum profiles with special specifications.

Aluminum Grade of Aluminum forges

Alloy Grade

1xxx, 2xxx, 3xxx, 4xxx, 5xxx, 6xxx, 7xxx, 8xxx

Tempers

Txxxx

Features of the company's products: there are many alloy brands, product specifications and stable performance, providing customers with a greater choice. There are more than 300 brands of 1XXX-8XXX series, including 1A99, 2A12, 2024, 2219, 2618, 2A50, 2A70, 5A06, 5083, 6082, 7075, 7050, 7A85, 7020, etc.

Supplier of Aluminum Forges

Staral alloy is a professional aluminum manufacturer providing different size and alloy types of aluminum products. Create reliable quality, let customer satisfaction is our pursuit. After the customer receives the goods, our after-sales personnel will follow up in time to provide perfect after-sales service.