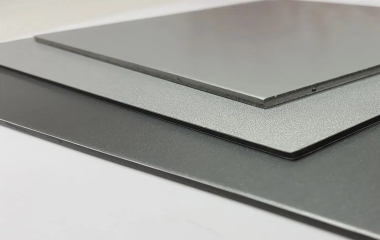

What is Aluminum Plate?

Aluminium Plate is highly resistant to corrosion, very ductile and has a reflective finish. It is roughly 1/3 the weight of mild steel, so that it is ideal for general sheet metal work where moderate strength is required but weight is an issue. Aluminum plate is straightforward to form or bend using hand tools or a bending brake. It also can be cut using a jigsaw with the correct blade, on a guillotine. Aluminum plate can be used for a wide range of applications from tooling plate, structural, general engineering, transport, agricultural, architectural, truck bodies, trailer parts ship and boat building.

Features of Aluminum Plate

1. Light (it’s approximately 1/3 the weight of iron and copper)

2. Ductile (it’s easy to work into new shapes and can undergo specific treatments)

3. Conductive (it has a higher thermal and electrical conductivity)

4. Resistant to corrosion (this characteristic can be improved with special coatings)

5. Recyclable (it can be indefinitely recycled without losing any of its fundamental properties)

Applications of Aluminum Plate

Due to the convenient and unique properties of aluminum sheets, their uses are also varied and extensive to provide a complete list of applications. This section presents some of the most common aluminum sheet applications that are easily found in a variety of everyday industries, construction sites and designs.

Roofing: Aluminum panels are ideal for roofing projects due to their lightweight yet strong construction. Additionally, the corrosion resistance of these panels increases the use of larger panels in roofing applications.

Ceilings: Composite aluminum panels and Dibond are generally suitable for indoor ceiling applications and large tiles. Due to their reflective, soft and aesthetic appearance, they offer a highly decorative and wear-resistant design.

Balconies: Once again, aluminum panels are widely used for balcony railings and fences due to their lightweight, waterproof and rigid properties.

Cladding and Exterior Walls: Aluminum composite panels have always been a leading product for exterior or façade, interior insulation and other applications in a wide variety of commercial, residential and industrial facilities and buildings. Architects all over the world prefer to use these products in their designs due to their resistance, finishes, coatings and ease of installation craftsmanship.

High Stress Applications: Medium-strength aluminum sheet structural alloys with excellent corrosion resistance are ideal for a range of force-intensive applications including aerospace and automotive structures.

Shelters: Aluminum panels are an effective material for building lightweight and durable shelters and walkways in workplaces, public areas and even private homes.

Floors and walls: Checked aluminum panels can provide anti-slip and damage-resistant properties, which are useful in high-traffic areas. In addition, decorative and perforated aluminum panels and walls are becoming increasingly popular in workplaces and homes as attractive, aesthetically pleasing and easy-to-clean fixtures.

Cable Sheathing: Cable metal sheathing is usually made of aluminum foil and sheet due to their corrosion resistance, easy handling process and electrical properties.

Support and Lifting Devices: Lightweight products for the lifting industry can increase productivity and reduce energy consumption. Machines and equipment that contain aluminum in their structure are easier to transport to the construction area.

Caravans: Storage and containment structures often incorporate aluminium and aluminium panels in their construction, making them lighter for transport and providing excellent resistance to weather conditions in areas with high exposure to different elements of damage.

How to cutomize aluminum plate?

Please contact customer service to provide your needs to customize aluminum plate.

Avilable Size for Aliminum Plate

| Size in mm | Theoretical mass (kg/plate) |

| 2000 × 1000 × 0.5 | 2.71 |

| 2500 × 1250 × 0.5 | 4.23 |

| 2000 × 1000 × 0.7 | 3.79 |

| 2500 × 1250 × 0.7 | 5.93 |

| 2000 × 1000 × 0.9 | 4.88 |

| 2500 × 1250 × 0.9 | 7.62 |

| 2000 × 1000 × 1.2 | 6.50 |

| 2500 × 1250 × 1.2 | 10.16 |

| 3000 × 1500 × 1.2 | 14.63 |

| 2000 × 1000 × 1.6 | 8.67 |

| 2500 × 1250 × 1.6 | 13.55 |

| 3000 × 1500 × 1.6 | 19.51 |

| 2000 × 1000 × 2.0 | 10.84 |

| 2500 × 1250 × 2.0 | 16.94 |

| 3000 × 1500 × 2.0 | 24.39 |

| 2500 × 1250 × 2.5 | 21.17 |

Aluminum Grade of Aluminum Plate

Alloy Grade

1xxx, 2xxx, 3xxx, 4xxx, 5xxx, 6xxx, 7xxx, 8xxx

Tempers

F, 0, Hxxx, Txxxx

| Alloy Series | Alloy | Temper | Thickness(mm) | Width(mm) | Major alloying element |

| 1*** Series | 1050 1060 1100 | F, HO, H12, H14, H16,H18, H22, H24, H26, H32,H111, H112, T4, T6, T351, T651 | 1.0-500mm | ≤3000(max) | Pure aluminium (99.0% and greater) |

| 2*** Series | 2A12 2024 2017 | Copper is major addition | |||

| 3*** Series | 3003 3105 | Manganese is major addition | |||

| 4*** Series | 4045 4047 4343 | Silicon is major addition | |||

| 5*** Series | 5052 5A02 5A03 5A055754 5083 5086 | Magnesium is major addition | |||

| 6*** Series | 6061 6063 6082 | Magnesium and silicon are major additions | |||

| 7*** Series | 7075 7A04 7050 7175 | Zinc is the major addition | |||

| 8*** Series | 8006 8011 8079 | Other Alloys | |||

| This is for reference only, product details to the actual subject. |

Supplier of Aluminum Plate

Staral alloy is a professional aluminum plate manufacturer providing different size and alloy types of aluminum plate. Common aluminum plate widths are 1000mm, 1250mm and 1500mm. Common lengths are 2000mm, 2500mm and 3000mm. Aluminum sheets can be cut according to customer requirements. Our aluminium sheets are available in a wide range of thicknesses from 3mm to 100mm. Thinner than 3mm is considered to be an aluminum plate. Aluminum sheet/sheet has excellent strength-to-weight ratio and natural corrosion resistance, making it popular in a wide range of applications. Aluminium and sheet metal are used in everything from aerospace and aircraft manufacturing to beverage packaging, cryogenic storage, siding, gutters and home roofing. If you are looking for high quality aluminum plate, feel free to send an inqiury and make a bulk order for aluminum plate.