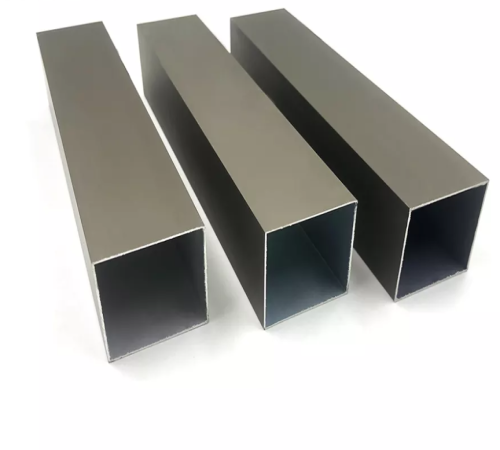

5052 Aluminum Alloy Tube

5052 Aluminum tube is a kind of nonferrous metal tube, which refers to the metal tubular material extruded from pure aluminum or aluminum alloy to be hollow along its longitudinal full length. There can be one or more closed through holes with uniform wall thickness and cross section, which are delivered in straight line or roll form. It is widely used in automobile, ship, aerospace, aviation, electrical appliances, agriculture, electromechanical, household and other industries.

Aluminium Grade: 5052

Shape: Customized, according to drawing.

Length:<=13m

Temper: O, H24, H34, H16, H26, H36, H18, H28, H38, H112, F,etc.

Certificate: DNV/ABS/Lioyds/BV

Packing: blank waterproof paper, kraft, wooden case or pallet (fumigation report for the wooden packing material)

Features: very good elongation, anti-corrosion performance

What is Aluminum tube?

Aluminum tube is a kind of nonferrous metal tube, which refers to the metal tubular material extruded from pure aluminum or aluminum alloy to be hollow along its longitudinal full length. There can be one or more closed through holes with uniform wall thickness and cross section, which are delivered in straight line or roll form. It is widely used in automobile, ship, aerospace, aviation, electrical appliances, agriculture, electromechanical, household and other industries.

Features of Aluminum tube

It is a kind of high-strength duralumin, which can be strengthened by heat treatment. It has medium plasticity in annealing, hard quenching and hot state, and good spot welding. When gas welding and argon arc welding are used, the aluminum tube tends to form intergranular cracks; The machinability of aluminum tube is good after quenching and cold work hardening, but it is not good in the annealing state. The corrosion resistance is not high. Anodic oxidation and painting methods are often used or aluminum coating is added on the surface to improve the corrosion resistance. It can also be used as die material.

Advantages of aluminum pipe: First, advantages of welding technology: thin wall copper aluminum pipe welding technology suitable for industrial production is called a world-class problem, and is the key technology of replacing copper with aluminum for connecting pipe of air conditioner.

Applications of Aluminum Tube

Aluminum tubes have the characteristics of corrosion resistance and light weight, and are widely used in various industries, such as automobiles, ships, aerospace, aviation, electrical appliances, agriculture, electromechanical, household and so on.

Supplier of Aluminum Tube

Staral alloy is a professional aluminum manufacturer providing different size and alloy types of aluminum products. Create reliable quality, let customer satisfaction is our pursuit. After the customer receives the goods, our after-sales personnel will follow up in time to provide perfect after-sales service.

Product Name | Aluminum Tube / Pipe | |

Aluminum Pipe | ||

Specifcation for round pipe | OD: 15nm-160nm | |

WT: 1-40mm | ||

Length: 1-12m | ||

Specification for square pipe | SIZE: 7X7mmm- 150X150 nlm | |

WT: 1-40mm | ||

Length: 1-12m | ||

Aluminum Rod | ||

Standard | ASTM B221M, GB/T 3191, JIS H4040,etc. | |

Material | 5052,5652, 5154, 5254, 5454, 5083, 2014,2014A,2214,2017,2017A,2117 | |

5086, 5056,5456, 2024, 2014, 6061, 6063,6082, etc. | ||

Diameter | 6-800mm | |

Length | 2m,3m,5.8m,6m,or as required | |

Surface | Mill finish,polished,anodizing,brushing,sand blasting,powder coating,etc | |

Send an Inquiry

Your email address will not published. Required fieled are marked.