6061 Aluminum Alloy Forgings

6061is a precipitation-hardened aluminium alloy, containing magnesium and silicon as its major alloying elements. It has good mechanical properties, exhibits good weldability, and is very commonly extruded. It is one of the most common alloys of aluminium for general-purpose use.

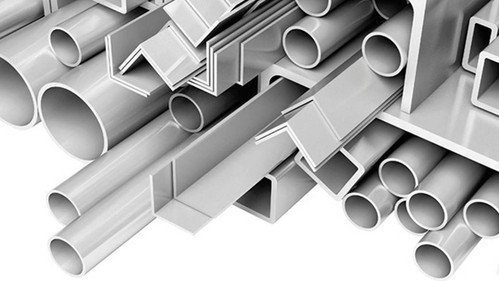

Aluminium Grade: 6061

Aluminum Forged Rings: 3″ OD up to 72″ OD

Aluminum Discs: 3″ DIA up to 72″ DIA

Aluminum Blocks: Up to 54″ Cross Section

Aluminum Flat Bar: 3″ OD up to 72″ OD

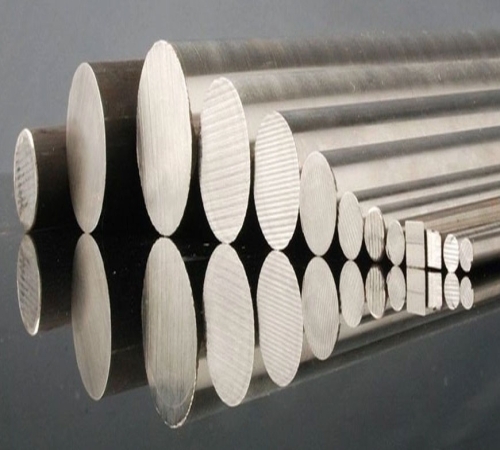

Aluminum Round Bars: 3″ OD up to 72″ OD

Temper: T6, T651, T6511, H112, O, T652, T5

Certificate: ISO9001, CNAS, OHSAS18001

Packing: blank waterproof paper, kraft, wooden case or pallet (fumigation report for the wooden packing material)

Features: very good elongation, anti-corrosion performance

Overview of 6061 Aluminum Alloy Forgings

6061 aluminum alloys function well in most situations and really stand as general-purpose aluminum stock to serve a wide variety of use cases. Anchor Harvey is proud to provide the highest quality forged 6061 aluminum products and to offer a variety of heat treatment options that can custom tailor material solutions to your needs.

Features of 6061 Aluminum Alloy Forgings

-Strength: Good strength that doesn’t compromise core structural integrity.

-Easy heat-treatability- This allows the material to be fitted to a wide variety of applications. The proper heat-treatment can make a given amount of 6061 Aluminum stock over twice as strong as its untreated counterpart.

-Machinability: 6061 Aluminum alloys are very easy to machine. Machining is necessary for many core components of large aerospace projects, and indeed where precision is needed anywhere. An easy-to-machine material guarantees customers a faster machining turnaround time, higher quality product, and lower overall costs.

-Weldability: Investing time and cost into complex and tough welding procedures can strain timelines and increase the risk of mistakes. 6061 aluminum stock is easy to weld, which makes the assembly process for many aerospace applications simpler and faster.

-Corrosion Resistance: 6061 aluminum has good resistance to environmental corrosion when compared to 2000 series aluminum. This is important for applications where the material is constantly exposed to the weather, especially in places where abrasion or wear is constant enough that protective coatings will be quickly worn away.

Applications of 6061 Aluminum Alloy Forgings

Forged 6061 Aluminum alloy has been in use since the mid-1930s. In the construction of aircraft structures, it often has more use in smaller aircraft frames. Still, its easy workability and affordability factor can make it popular for aircraft repairs and small structural components. Its chief rival in this area is 2024 Aluminum, which is commonly used in large aircraft frames due to its higher strength, though 6061 takes the edge with its natural corrosion resistance.

Other uses for forged 6061 aluminum alloy stock include the following: Bicycle frames and chains, fly fishing reels, firearm suppressors (specifically baffles and chamber housings), rifle receivers, dockyard planks and gangways, vacuum chambers, model aircraft, hobby planes, radio antennas, rescue ladders, and flashlights. In fact, the gold anodized aluminum plaques on the Pioneer 10 and Pioneer 11 spacecraft are made with 6061 aluminum.

Manufacturer of 6061 Aluminum Alloy Forgings

Staral Alloy is a professional aluminum supplier, providing users with different types of aluminum products. The price of aluminium is not only low, but also has high corrosion resistance. We strictly control the production process of each product to ensure high quality.

Chemical properties

AL | MG | SI | FE | CU | CR | ZN | TI | MN |

95.85 - 98.56% | 0.8 - 1.2% | 0.40 - 0.8% | 0.0 - 0.7% | 0.15 - 0.40% | 0.04 - 0.35% | 0.0 - 0.25% | 0.0 - 0.25% | 0.0 - 0.15% |

Mechanical properties

GRADE | STRENGTH (METRIC/IMPERIAL) | HARDNESS | ||

Temper | Ultimate Tensile Strength | Yield Strength | Brinell | Rockwell |

6061-T6 | 310MPa or 42,000 KSI | 270 MPa or 39,000 KSI | 95 | B60 |

6061-T6511 | 290 MPa or 45,000 KSI | 270 MPa or 40,000 KSI | 95 | B60 |

Send an Inquiry

Your email address will not published. Required fieled are marked.