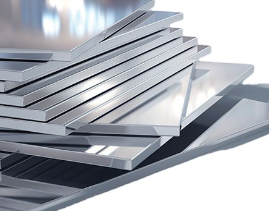

5052 Aluminium profiles

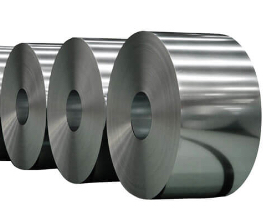

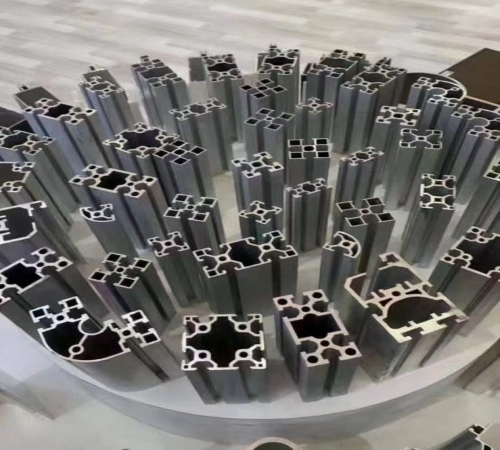

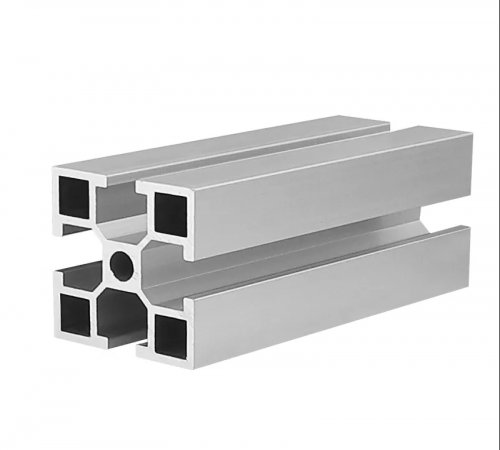

Aluminum profiles are also known as aluminum extruded profiles. Extrusion profile is the process of pushing the heated aluminum blank through the required cross section die through a certain pressure. The formed profile is light in weight, high in strength, corrosion resistant, and similar in shape to the die opening. Generally, the die is made of hard steel or hard alloy. There are two conventional methods for aluminum extrusion, direct extrusion (the same as forward extrusion) and indirect extrusion (the same as reverse extrusion). There are many classification methods for aluminum profiles. According to aluminum materials, aluminum profiles can be divided into 1100 aluminum profiles, 6061 aluminum profiles and 6063 aluminum profiles. According to different uses, it can be divided into architectural aluminum profiles, industrial aluminum profiles, etc.

Aluminium Grade: 5052

Width: Customized

Thickness: Customized

Temper: O,H112 etc.

Certificate: DNV/ABS/Lioyds/BV

Packing: blank waterproof paper, kraft, wooden case or pallet (fumigation report for the wooden packing material)

Features: good corrosion resistance, good machinability, and excellent welding capabilities, good strength-to-weight ratio and highly versatile.

Overview of 5052 Aluminium Alloy Profile

Aluminum profiles are also known as aluminum extruded profiles. Extrusion profile is the process of pushing the heated aluminum blank through the required cross section die through a certain pressure. The formed profile is light in weight, high in strength, corrosion resistant, and similar in shape to the die opening.

Features of Aluminum Profile

1. Corrosion resistance

The density of aluminum profile is only 2.7 g/cm3, which is about 1/3 of the density of steel, copper or brass (7.83 g/cm3, 8.93 g/cm3 respectively). Under most environmental conditions, including air, water (or salt water), petrochemical and many chemical systems, aluminum can show excellent corrosion resistance.

2. Conductivity

Aluminum profiles are often selected because of their excellent conductivity. On the basis of equal weight, the conductivity of aluminum is nearly 1/2 that of copper.

3. Thermal conductivity

The thermal conductivity of aluminum alloy is about 50-60% of copper, which is beneficial to the manufacture of heat ex changers, evaporators, heating appliances, cooking utensils, as well as automobile cylinder heads and radiators.

4. Non ferromagnetic

Aluminum profiles are non ferromagnetic, which is an important characteristic for electrical and electronic industries. Aluminum profiles are not self igniting, which is important for applications involving handling or contacting flammable and explosive materials.

5. Machinability

The machinability of aluminum profiles is excellent. In a variety of wrought and cast aluminum alloys, as well as in various states after the production of these alloys, machining characteristics change considerably, which requires special machine tools or technologies.

6. Formability

The specific tensile strength, yield strength, ductility and corresponding work hardening rate control the change of allowable deformation.

7. Recyclability

Aluminum has very high recoverability, and the characteristics of recycled aluminum are almost the same as that of primary aluminum.

Technique specifications of Aluminum Plate

| Element | % Present |

| Si | 0.4 |

| Fe | 0.4 |

| Cu | 0.1 |

| Mn | 0.4-1.0 |

| Mg | 4.0-4.9 |

| Zn | 0.25 |

| Ti | 0.15 |

| Cr | 0.05-0.25 |

| Al | Balance |

Mechanical Specifications of Aluminm Plate:

| Property | Value |

| Proof Stress | 110 Min MPa |

| Tensile Strength | 170-360MPa |

| Yield strength | ≥65MPa |

| Modulus of elasticity(E) | 69.3~70.7Gpa |

Send an Inquiry

Your email address will not published. Required fieled are marked.