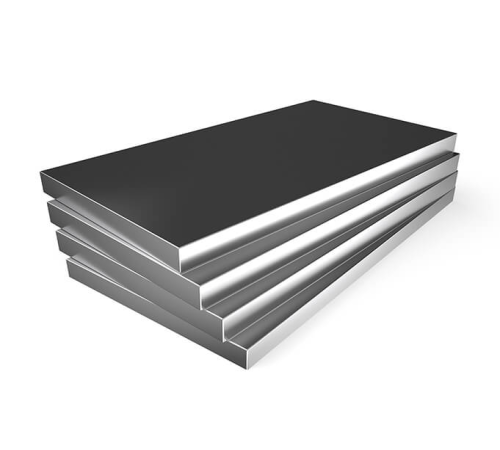

5083 Aluminum Alloy applied in ASU

5083 aluminium plate also retains exceptional strength after welding. It has the highest strength of non-heat-treatable alloys. 5083 aluminium is known for its exceptional performance in extreme environments. It is highly resistant to attack by both seawater and industrial chemical environments. And 5083 aluminum plate also retains exceptional strength after welding. It has the highest strength of the non-heat-treatable alloys but is not recommended for use in high temperatures environments.

Aluminium Grade: 5083

Width: 500-2500mm

Thickness: 0.5-35mm

Length: 500-10000mm

Temper: O, H116, H112, H14, H22, H24, H32, H111, H16, H36, F,etc.

Certificate: DNV/ABS/Lioyds/BV

Packing: blank waterproof paper, kraft, wooden case or pallet (fumigation report for the wooden packing material)

Features: very good elongation, anti-corrosion performance

Overview of 5083 Aluminium Alloy

5083 aluminum alloy has higher strength and better thermal conductivity than 5052 aluminum alloy. In the tempered condition, it maintains good formability due to its excellent ductility. Ideal for welding and can be cold work hardened. Due to its excellent general corrosion resistance properties, 5083 aluminum alloy can be used in marine applications. Alloy 5083 is especially suitable for the cryogenic market because it can withstand extremely low temperatures without becoming brittle or losing properties. Alloy 5083 has been used in vehicle armor plates due to its high strength factor.

Features of 5083 Aluminum Alloy

1. Corrosion resistance

It is susceptible to stress corrosion cracking, which limits its application temperature to below 65°C and limits the amount of cold work to ¼ Hard.

2. Heat treatment

The hardness of 5083 aluminum alloy cannot be enhanced by heat treatment. It can be significantly hardened by cold working (cold rolling) and produces various "H" tempers - most commonly H32 (¼ hard) or similar strength marine tempers H116 and H321 - as well as soft annealed O tempers.

3. Welding

Almost all standard electric welding of 5083 aluminum alloy has excellent weldability, GMAW and GTAW are preferred and widely used to produce structural welds.

Applications of 5083 Aluminum Alloy

ASU: Air Separation Unit

Manufacturer of 5083 Aluminum Alloy

Staral Alloy is a professional aluminum supplier, providing users with different types of aluminum products. The price of aluminium is not only low, but also has high corrosion resistance. We strictly control the production process of each product to ensure high quality.

Technique specifications of 5083 Aluminum Alloy

Element | % Present |

Si | 0.4 |

Fe | 0.4 |

Cu | 0.1 |

Mn | 0.4-1.0 |

Mg | 4.0-4.9 |

Zn | 0.25 |

Ti | 0.15 |

Cr | 0.05-0.25 |

Al | Balance |

Mechanical Specifications of Aluminium Alloy

Property | Value |

Proof Stress | 110 Min MPa |

Tensile Strength | 170-360MPa |

Yield strength | ≥65MPa |

Modulus of elasticity(E) | 69.3~70.7Gpa |

Send an Inquiry

Your email address will not published. Required fieled are marked.