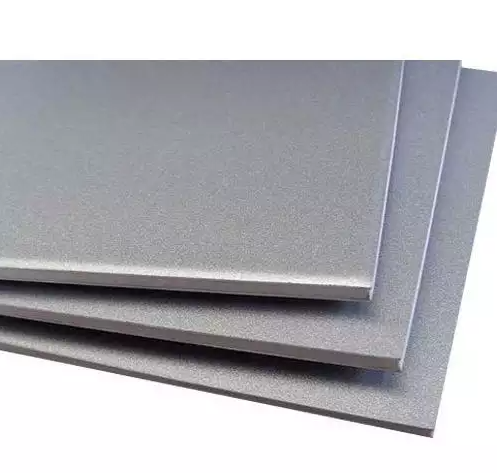

5754 Aluminum Alloy Plate

5754 aluminum plate is a high strength non-heat treatable alloy with excellent corrosion resistance, good weldability and machinability. It is particularly good for seawater applications.

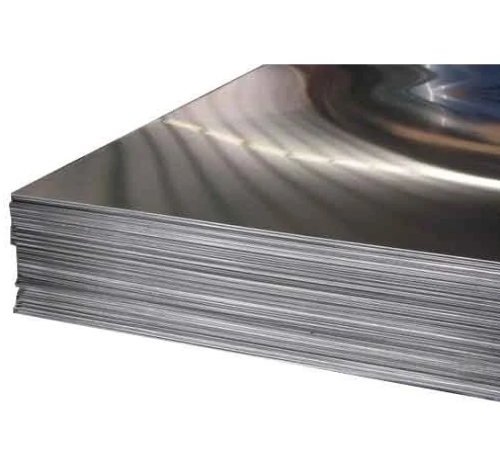

Aluminium Grade: 5754

Width: 800mm-4300mm

Thickness: 6mm-300mm

Length: 2000mm-38000mm

Temper: O,H111,H12, H22, H32, H14, H24, H34, H16, H26, H36, H18, H112, F, etc.

Certificate: DNV/ABS/Lioyds/BV

Packing: blank waterproof paper, kraft, wooden case or pallet (fumigation report for the wooden packing material)

Features: very good elongation, anti-corrosion performance

Overview of 5754 Aluminium Alloy Plate

Aluminium 5754 has excellent corrosion resistance especially to seawater and industrially polluted atmospheres. It has higher strength than 5251. This high strength makes 5754 highly suited to flooring applications. Please note that Mechanical Properties shown are for H22.

Features of 5754 Aluminium Alloy Plate

It has low density, is non-toxic, has a high thermal conductivity, has excellent corrosion resistance and can be easily cast, machined and formed. It is also non-magnetic and non-sparking. It is the second most malleable metal and the sixth most ductile.

Applications of 5754 Aluminium Alloy Plate

-Treadplate

-Shipbuilding

-Vehicle bodies

-Rivets

-Fishing industry equipment

-Food processing

-Welded chemical and nuclear structures

Manufacturer of 5754 Aluminium Alloy Plate

Staral Alloy is a professional aluminum supplier, providing users with different types of aluminum products. The price of aluminium is not only low, but also has high corrosion resistance. We strictly control the production process of each product to ensure high quality.

Chemical composition for 5754 Aluminium Alloy Plate

| Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ot | Total | Total |

0.4 | 0.4 | 0.1 | 0.5 | 2.6 - 3.6 | 0.3 | - | 0.2 | 0.15 | 0.05 | 0.15 | Remainder |

Mechanical Properties of 5754 Aluminium Alloy Plate

Mechanical Properties of Aluminium 5754 | |

BS EN 485-2:2008 | |

Property | Value |

Proof Stress | 60 Min-190 Min MPa |

Tensile Strength | 160-305 MPa |

Elongation A50 mm | 4- 12 Min % |

Hardness Brinell | 44 -78 HB |

*Properties above are for material in the H111 H114 H22 H24 H26 condition. | |

Some thicknesses have a slightly higher minimum elongation requirement. | |

Send an Inquiry

Your email address will not published. Required fieled are marked.